News

-

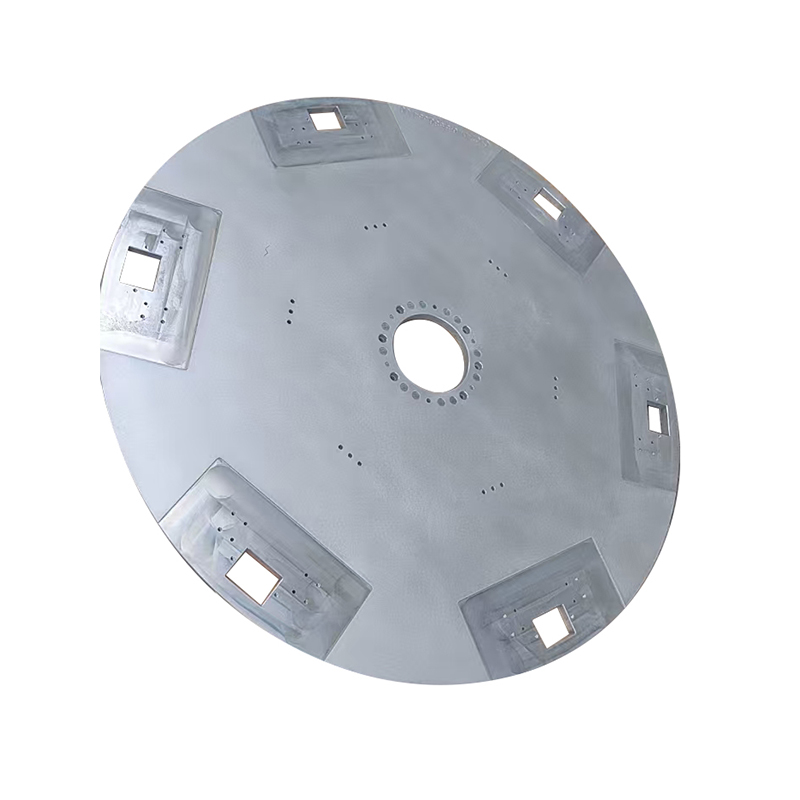

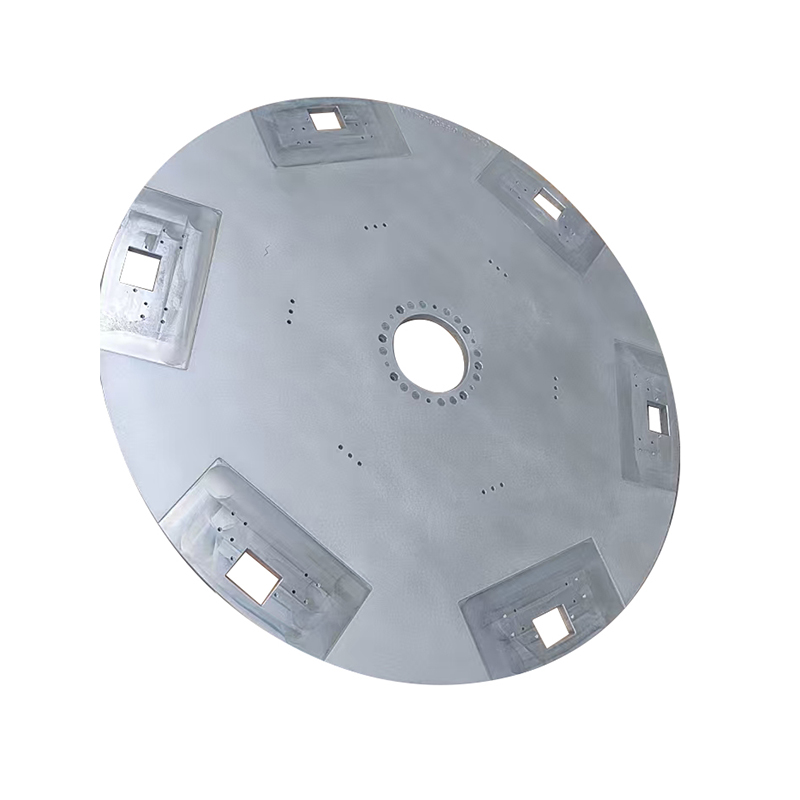

How to ensure dynamic balancing accuracy when a precision disc is rotating at high speed?

During transportation, installation and use, the balance of the disc may be altered due to collisions or vibrations. Therefore, regular re-inspection is an important measure to ensure its long-term stable operation.

Learn More2025-12-18 -

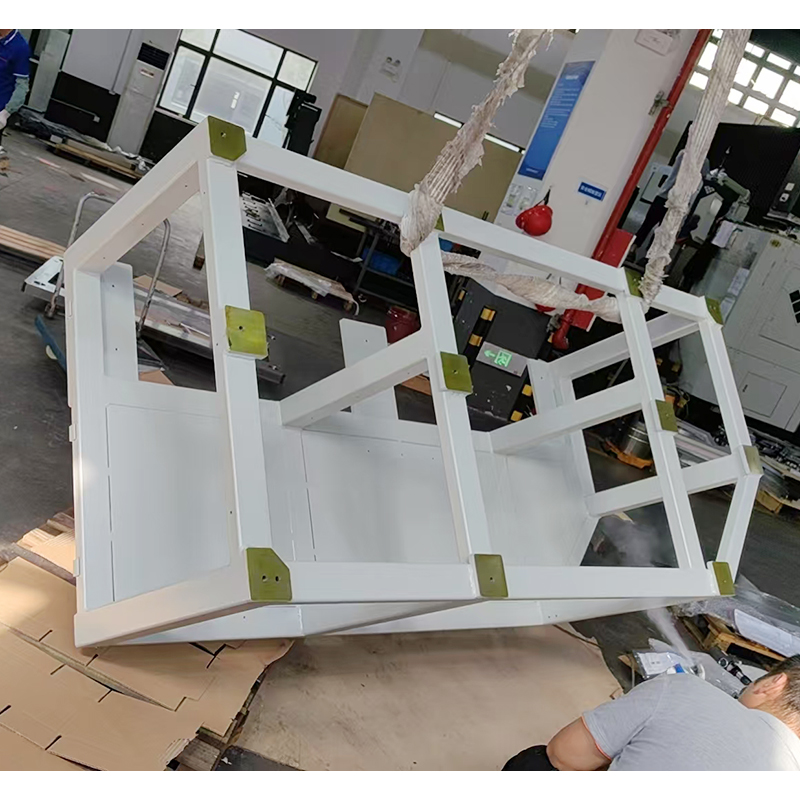

How to properly perform post-heating and hydrogen removal treatment after welding parts?

Welded parts should be kept away from humid air or corrosive media during the heating and heat preservation stages to prevent surface oxidation or hydrogen re-penetration.

Learn More2025-12-09 -

Exploring the Technological Wonders Within Precision Small Parts

Precision small parts are the "micro-foundation" of a manufacturing powerhouse. Behind them lies the challenge of pushing limits, the dedication to detail, and the mastery of interdisciplinary integration. As the ancients said, "Great things in the world

Learn More2025-12-05 -

How to set welding parameters to ensure a neat weld when welding parts?

The gas flow rate needs to be adjusted according to the welding current and speed to effectively protect the molten pool without interfering with the stability of the arc.

Learn More2025-11-25 -

How to ensure the precision control of track spacing in the manufacturing process of precision discs?

The precision control of the track spacing of a precision disc is the result of the cross-integration of materials science, optical engineering, and precision manufacturing.

Learn More2025-11-21 -

How to analyze the causes of cracks in welding parts from a process perspective?

If a part has sharp corners, notches, or abrupt changes in cross-section, stress will concentrate at these points during welding, causing cracks when the stress exceeds the material's plastic deformation capacity.

Learn More2025-11-11